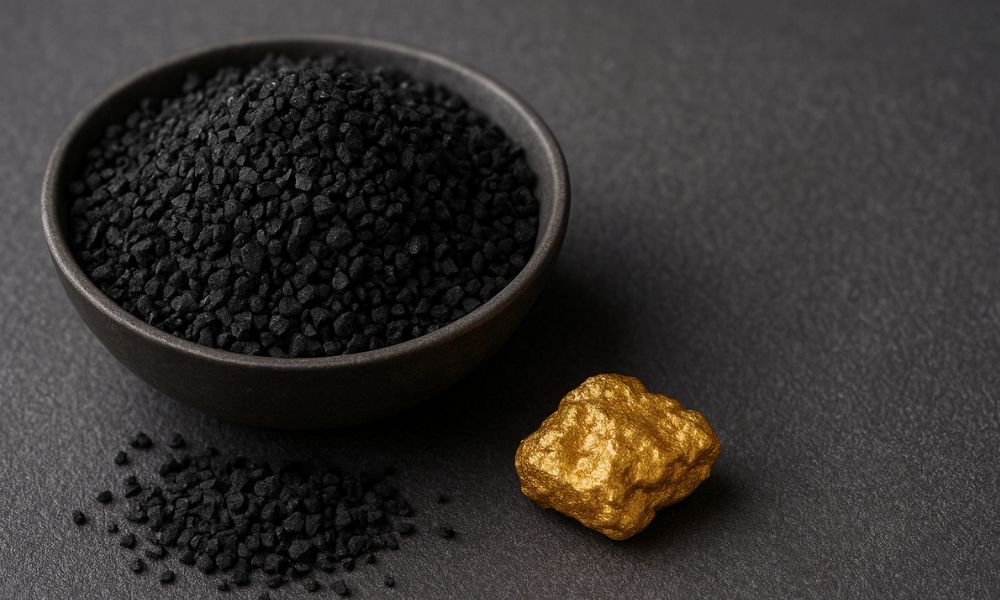

Activated carbon with a high floatation rate is not suitable for gold refining because it leads to inappropriate gold refining. Gold must be efficiently extracted from carbon-in-pulp (CIP) or carbon-in-leach (CIL) processes. When activated carbon high floatation rate rises and disperses in the slurry instead of settling and mixing as it should. Poor gold recovery results from the carbon and gold-loaded solution having less time to come into contact.

Gold is a highly valuable and liquid asset, and its demand is increasing. Gold refining is the process of purifying raw gold, often extracted from natural resources or recycled sources, through various processes. This process is carried out to achieve high purity. Common methods of gold refining include cyanidation, electrolysis, and carbon adsorption, depending on the material and desired purity.

It is the ability to load gold further diminished by floating carbon, which could be a sign of insufficient activation or incorrect density. High-density, low floatation carbon is given priority in refineries to guarantee effective gold adsorption, low losses, and reliable process performance. Therefore, to maintain optimal recovery, carbon with high floatation is rejected during the gold refining process.

What are the factors activated carbon with a high floatation rate unsuitable for gold refining?

If the activated carbon has with high flotation rate, it becomes inefficient and problematic for gold recovery. There are multiple reasons, which are the following:

1. Poor Adsorption Efficiency: Gold adsorption requires prolonged contact with the resources and carbon. But when it comes to floating carbon, it reduces the interaction, which leads to lower gold recovery rates.

2. Operational challenges: high flotation-rated carbon may lead to a rise and accumulate at the surface of the slurry mixture. This may lead to uneven gold loading.

3. Increased losses: floating carbon is more likely to be carried away, causing the gold elements may also be lost. It easily leads to material losses and higher operational costs.

4. Density and structure problems: When the process of gold refining is undergone, an alert should be given for selecting dense carbon that can sink easily. High floatation carbon as the name suggests it tends to float more than dense, reducing gold loading capacity.

There on the closing note it can be concluded for gold refining carbon with low flotation, high hardness, and optimal pore structure to maximize gold recovery at the same maintaining heavy losses.

Why is activated carbon with a high flotation rate not suitable for gold refining?

Traditional methods of gold extraction include the use of many toxic substances, along with hazardous impacts on health. Activated carbon helps to extract gold, causing comparatively reduced hazards to our health; it is an advanced way of extracting gold compared to the other methods followed in ancient times. Most modern technology is followed by activated carbon because of its reusability and recycling. It can be regenerated and recycled multiple times. After the gold is extracted and collected, the carbon is later heated and then reserved for use again in the same cycle of the process. However, not all carbon is ideal for refining; particularly carbon with a high floatation rate is recommended.

From the name itself, we can derive that carbon tends to remain floating in the liquid solutions rather than settling properly. This makes it difficult to separate from the gold-cyanide solutions during the refining process, leading to inefficiency in the gold metal refining.

Standard activated carbon can be easily recovered and regenerated, but floating carbon complicates the process, increasing operational costs and reducing recovery rates, resulting in an optimal usage of activated carbon.

Additionally, high-flotation carbon may carry impurities into the final gold product, affecting purity levels. Since gold refining requires precise separation and high recovery efficiency, using carbon with poor setting properties can hinder performance.

What are the benefits of Activated Carbon in Gold Refining?

The usage of activated carbon helps in higher rates of gold recovery and refinement due to less wastage compared to the traditional methods. It also allows companies to extract more gold from the same amount of ore, reducing wastage and operational costs. It increases the productivity of gold extraction by speeding up the process by investing more time in the gold collection. Activated carbon is a cost-effective solution for gold refining, as it is reusable and can be regenerated multiple times, thereby increasing its user-friendliness. Its efficiency means fewer resources are required to extract gold.

Why southern carbon for activated carbon in the USA?

US tariffs would likely reduce India’s competitiveness in the US activated carbon market unless offset by strong global demand. Charcoal price increases are driving up GAC production costs, leading to supply shortages and higher market volatility, with no immediate relief expected. Strategic actions will be crucial for businesses to manage risks in 2025-2026.

In this challenging market environment, the following recommendations are crucial for activated carbon:

- Secure Supply Early: Prudent governance dictates securing necessary GAC volumes at current price levels. The likelihood of future reductions in freight or GAC prices appears low.

- Adopt a Stock-and-Sell Model: Given the prevailing conditions of scarcity and rising prices, a stock-and-sell approach is projected to be more profitable than relying on back-to-back sales.

- Implement Transparent and Dynamic Pricing: Adopt a rolling review pricing strategy, potentially for every lot size of approximately 100-200Mt, in close collaboration with GAC.

- Manufacturers or the Suppliers, to ensure prices are aligned with the rapidly evolving market conditions.

However, Southern Carbon serves to be the best activated carbon manufacturer in the USA. The charcoal price surge has led to higher GAC prices, reduced supply availability, and increased competition, making the market more volatile. Manufacturers must adopt strategic stockpiling and dynamic pricing to navigate these challenges.

The US, the largest importer of activated carbon, could impose higher tariffs on Indian exports, potentially increasing export costs and reducing competitiveness. Southern Carbon is the most appropriate and leading activated carbon company in the USA. Visit our website and contact us for further information.